Research

Team

Publications

News

|

New Publication: Design and Deformation Analysis of an Inflatable Metallic Cylinder Based on the Kresling Origami Pattern

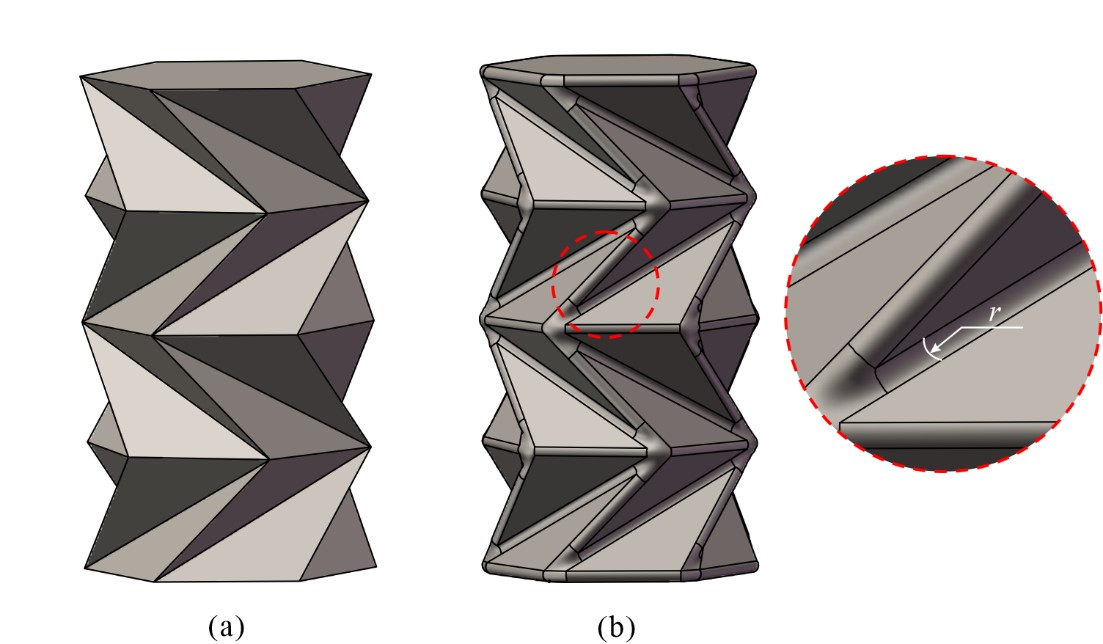

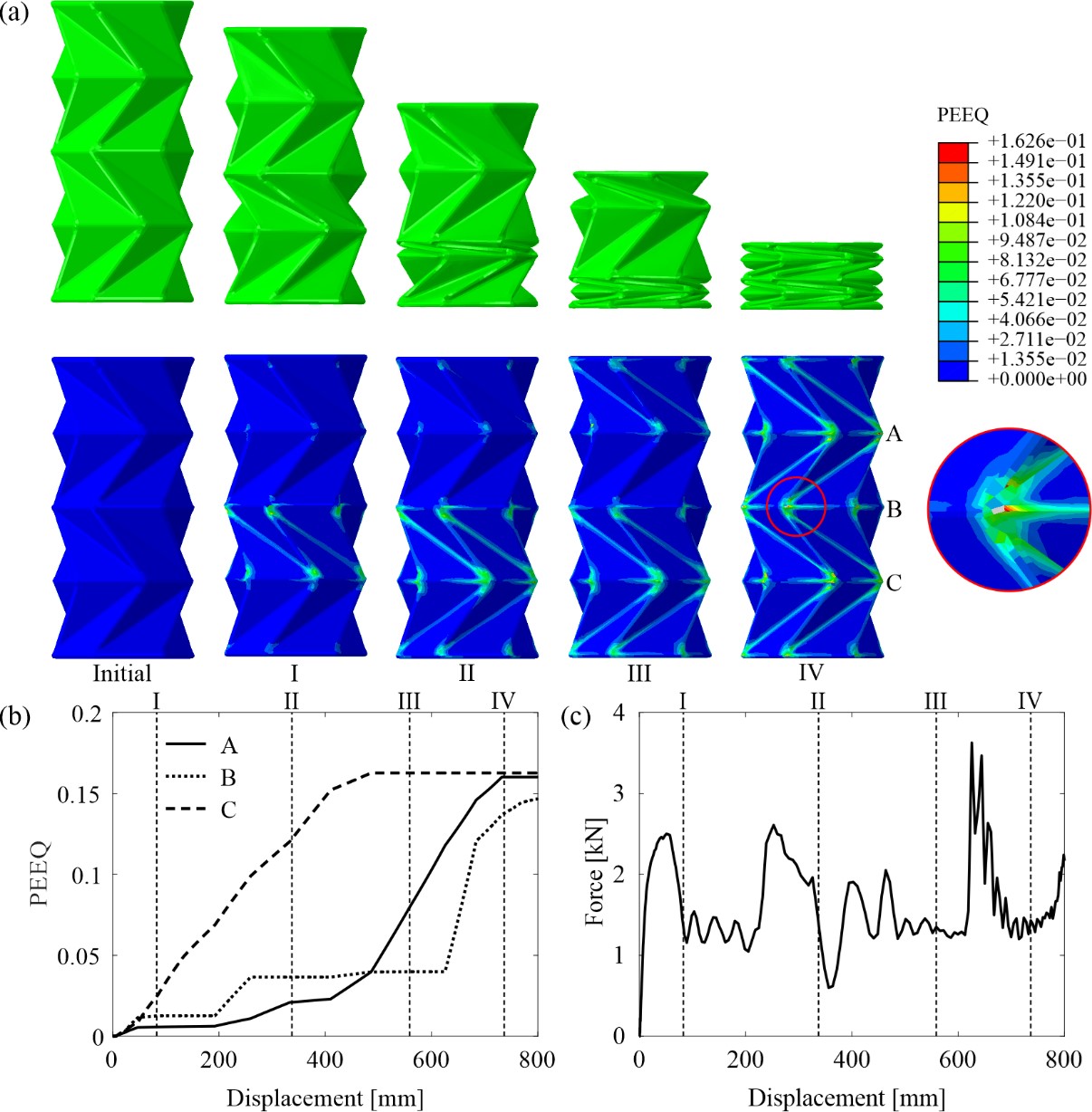

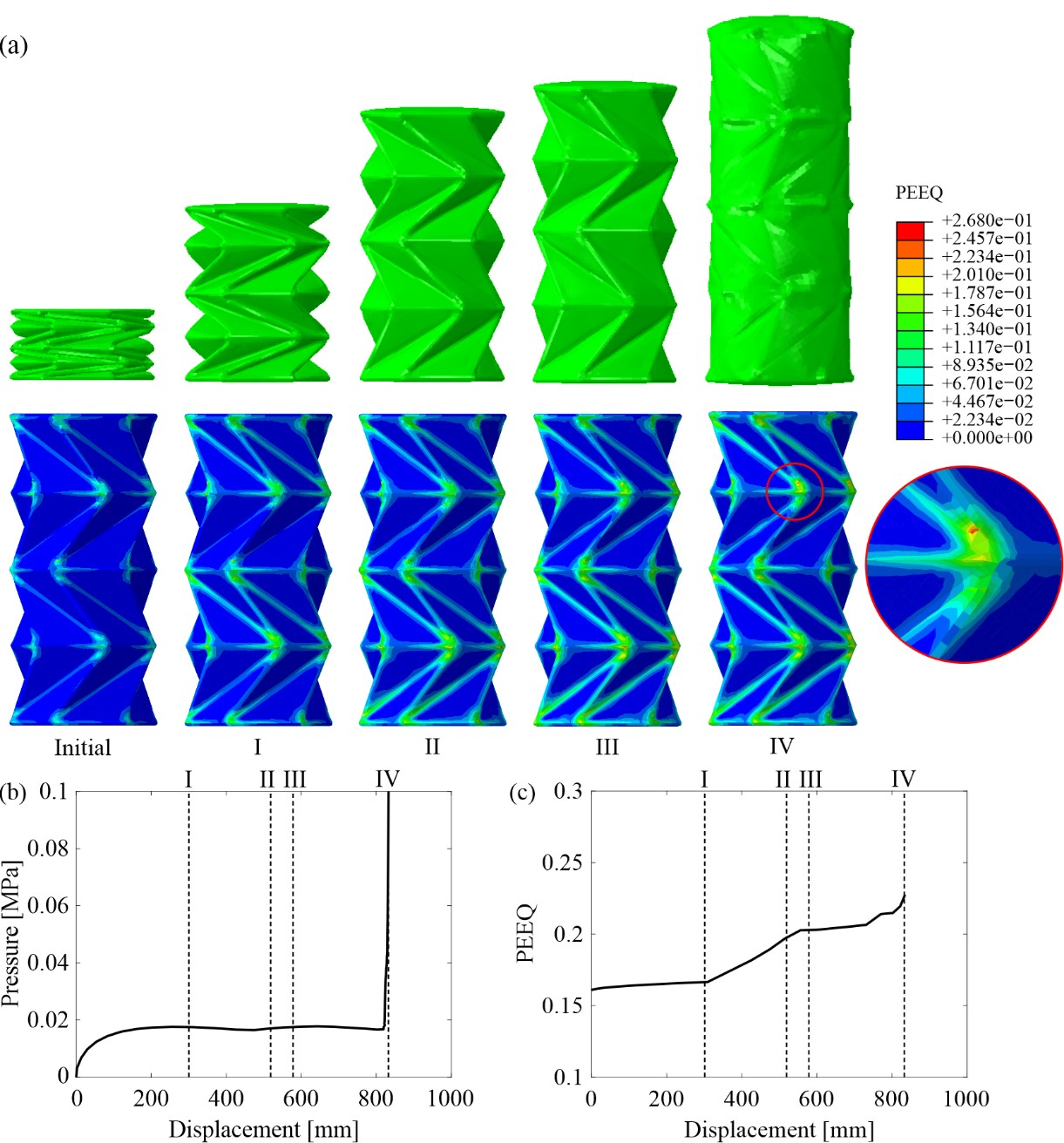

From: Date: 2023-05-31 Inflatable space capsules can be compactly folded to a small volume during launch and then deployed in space to create a large enclosed place for astronauts and equipment. Current inflatable space capsules are usually made of soft composite materials and need to be rigidized after deployment, but the ridigization techniques to date can not meet the requirements of high stiffness and low thermal expansion simultaneously. Figure 1 The Kresling cylinder (a) without transition arc creases and (b) with transition arc creases. Then, the numerical models are established and validated by the experiments. Figure 2 (a) A series of male and female molds; (b) Experimental setup of axial compression; (c) and (d) Comparison between experimentally and numerically obtained force versus displacement curves and deformation processes. This paper has proposed an inflatable metallic cylinder based on the Kresling origami pattern. The influences of design parameters during the folding and inflatable deployment process on the deployment ratio and the maximum plastic strain of the cylinder have been analyzed and discussed. The effects of the design parameters show the same trend in both processes. And the design parameters affect the deployment ratio and maximum plastic strain of the cylinder through the number of transition arc creases and its radius. Specifically, the maximum plastic strain reduces with the total number of creases, but a large number of creases will lead to a lower deployment ratio. An increase in transition arc radius reduces both the deployment ratio and the maximum plastic strain. Figure 3 (a) The folding process and its corresponding PEEQ contour maps, (b) PEEQ history of the typical six-crease vertices during the folding process, and (c) Force versus displacement curve. Figure 4 (a) Inflatable deployment process and corresponding PEEQ contour maps, and (b) pressure versus displacement curve; (c) PEEQ history of a six-crease vertex during deployment. This work was accepted by Thin-Walled Structures on 14 May, 2023 and published online on 30 May. The work in this paper provides reference for the design of inflatable metal cylinders.

M. Li, Z. Zhou, B. Hao, C. Yu, Y. Chen, J. Ma*, Design and deformation analysis of an inflatable metallic cylinder based on the Kresling origami pattern, Thin-Walled Struct. 188 (2023) 110859. |