Research

Team

Publications

News

|

New Publication: Advanced Intelligent Systems | Zhenhao Jia published A Multimode Soft Robot Based on a Single Braided Tube

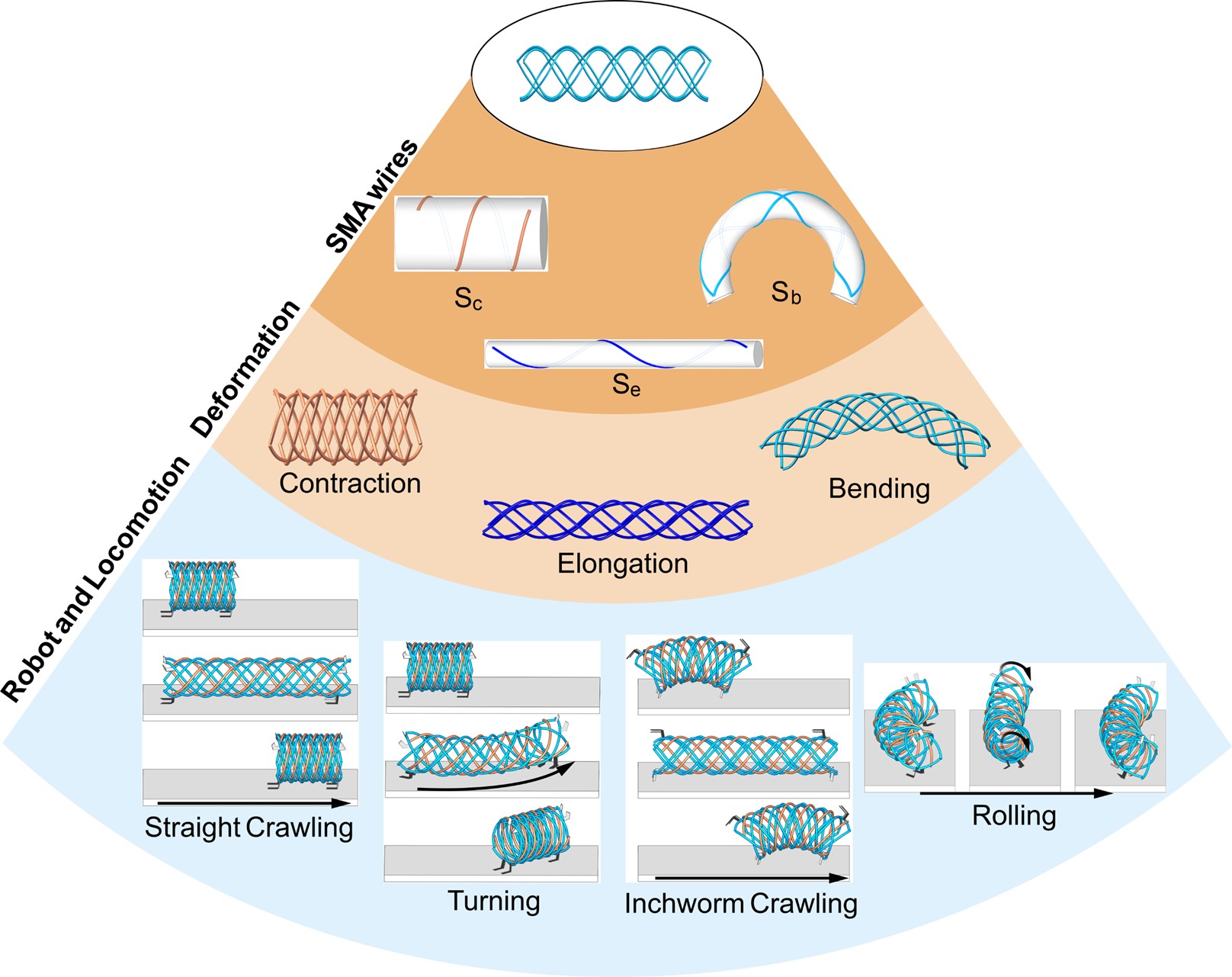

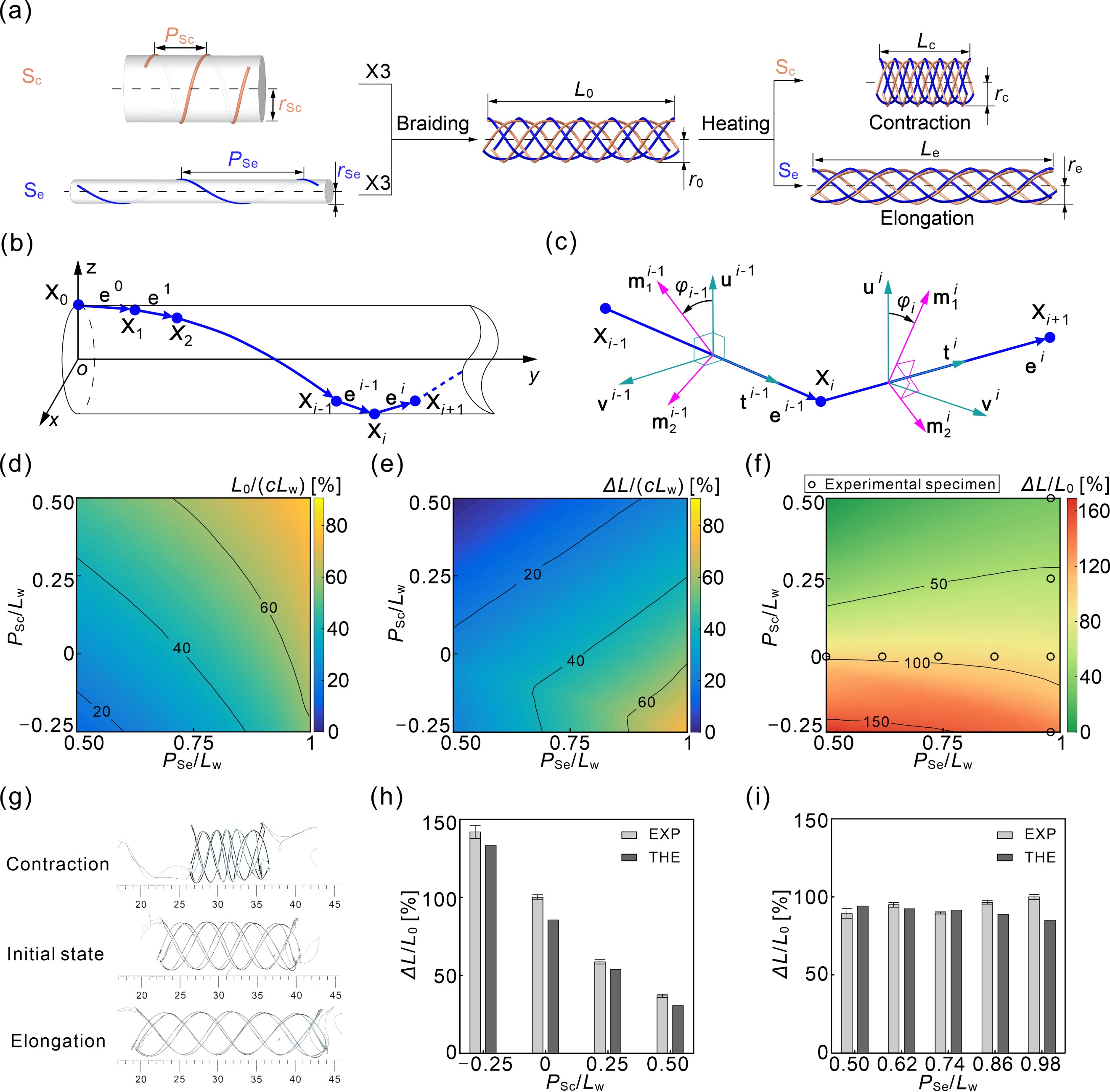

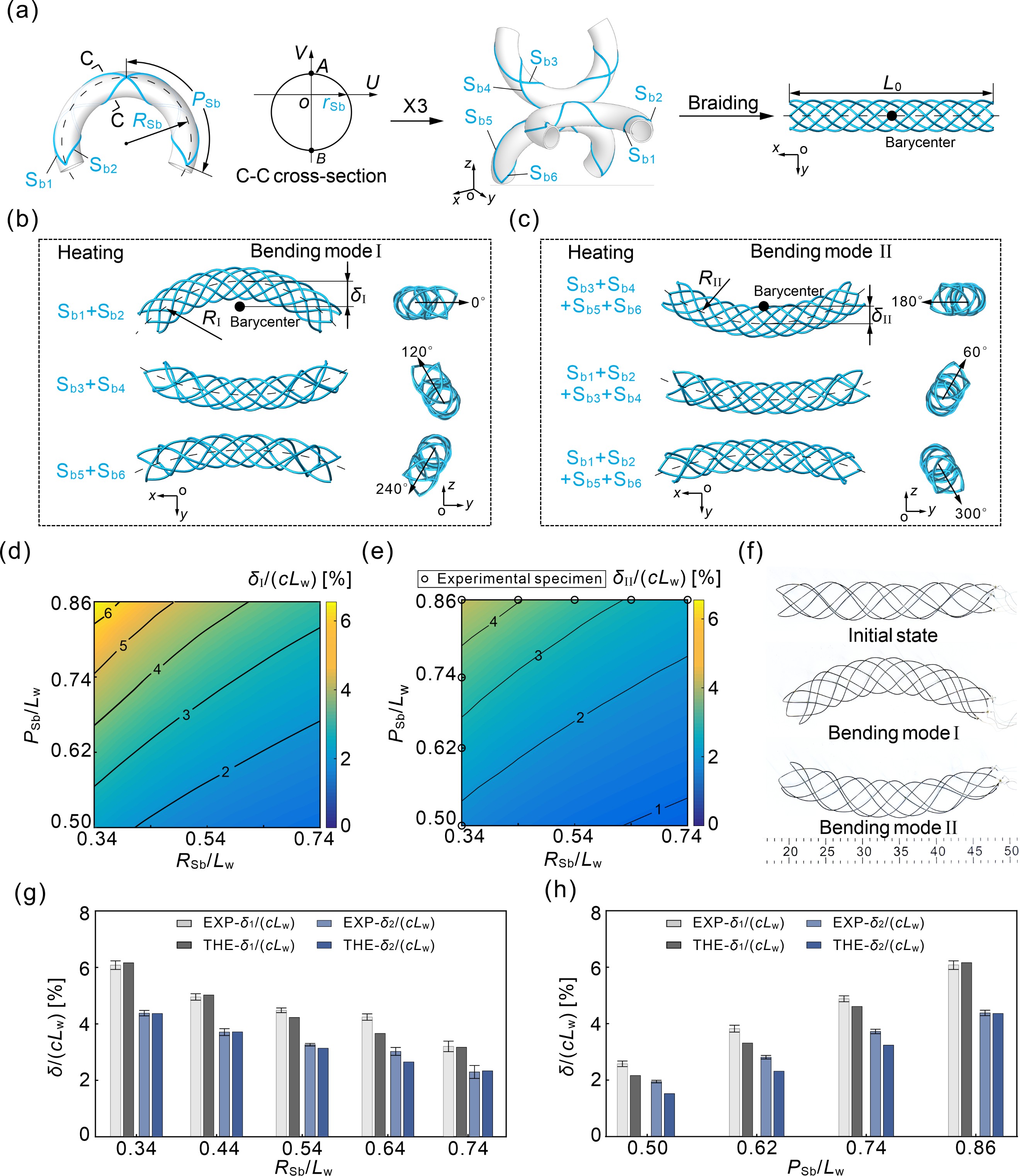

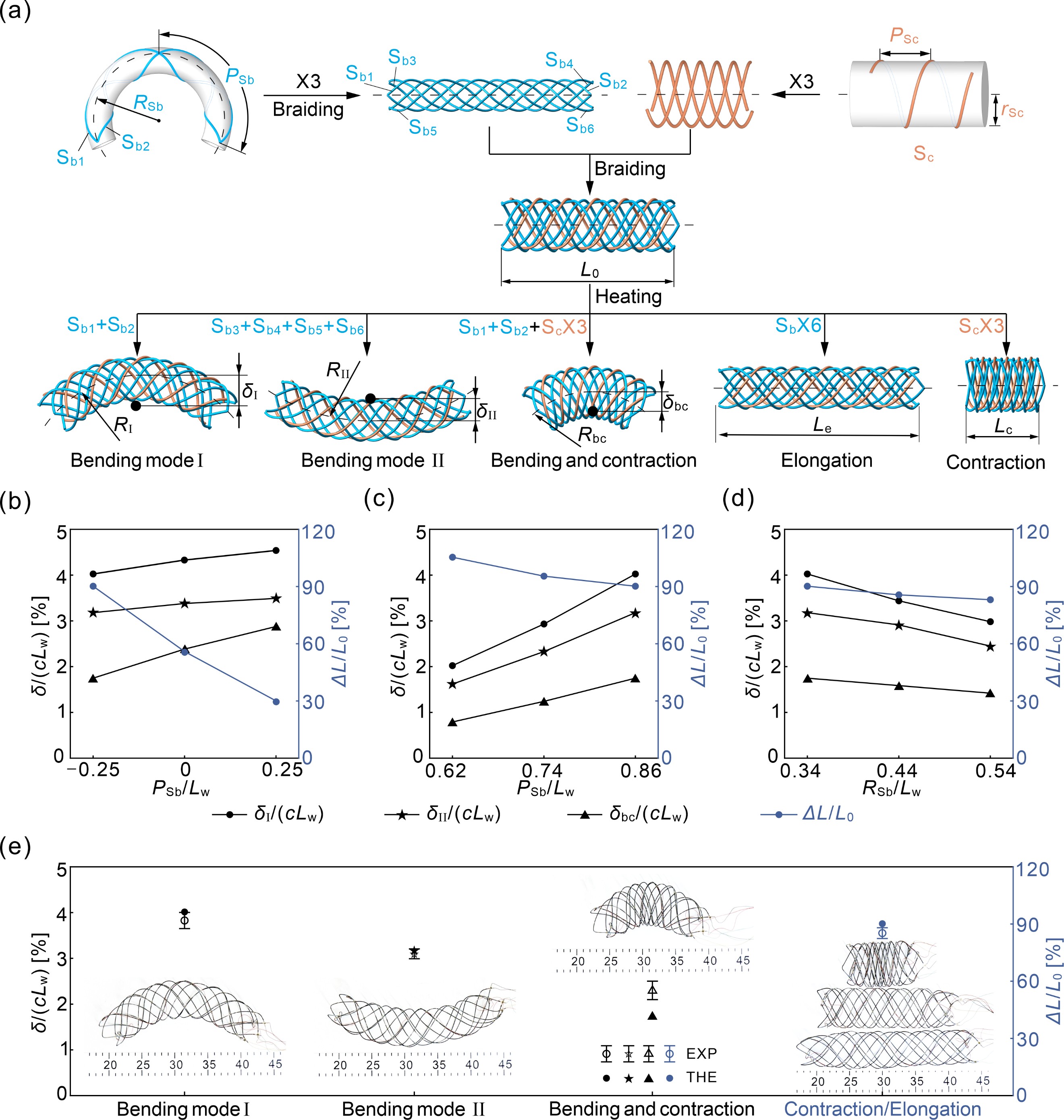

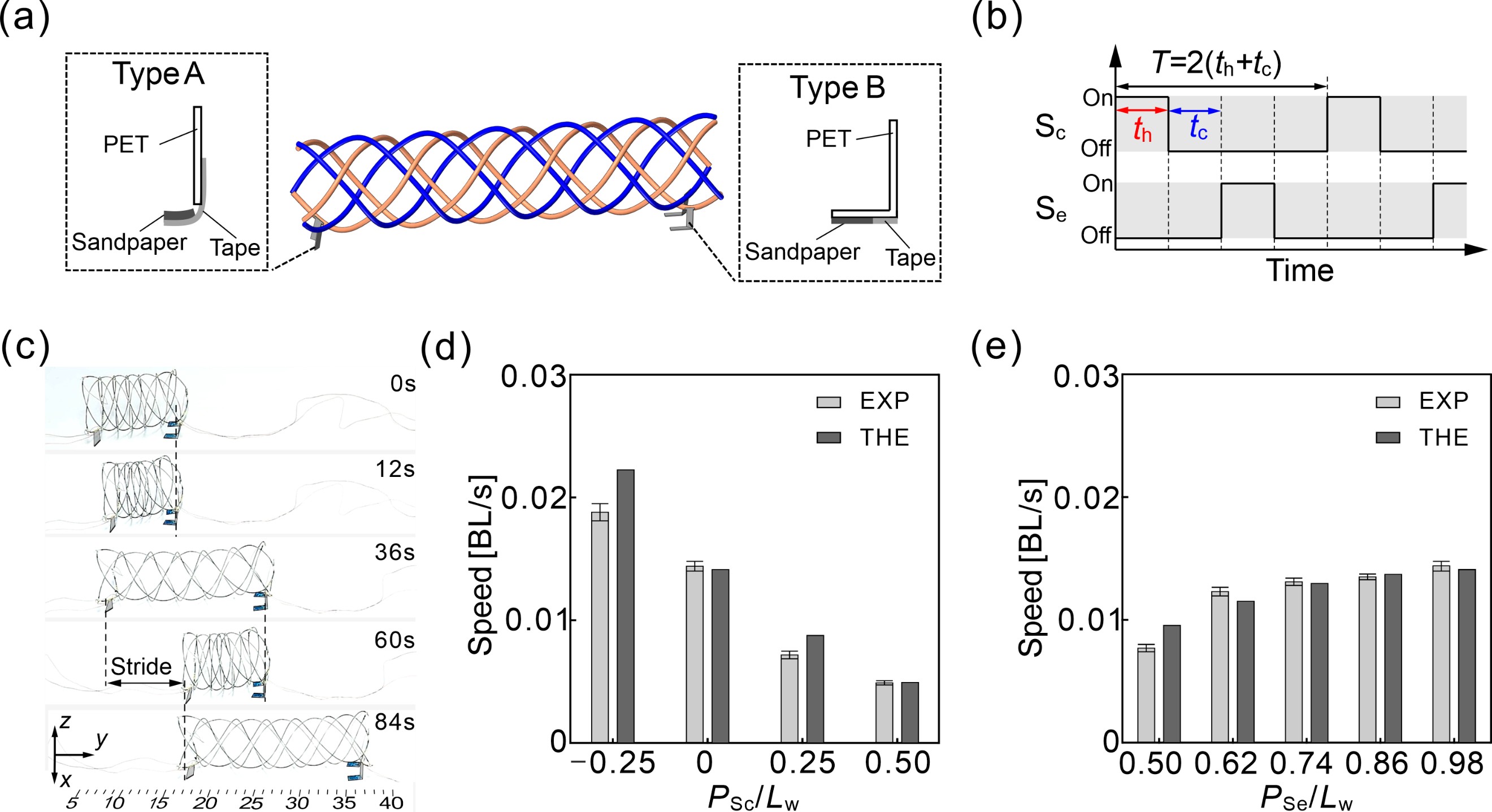

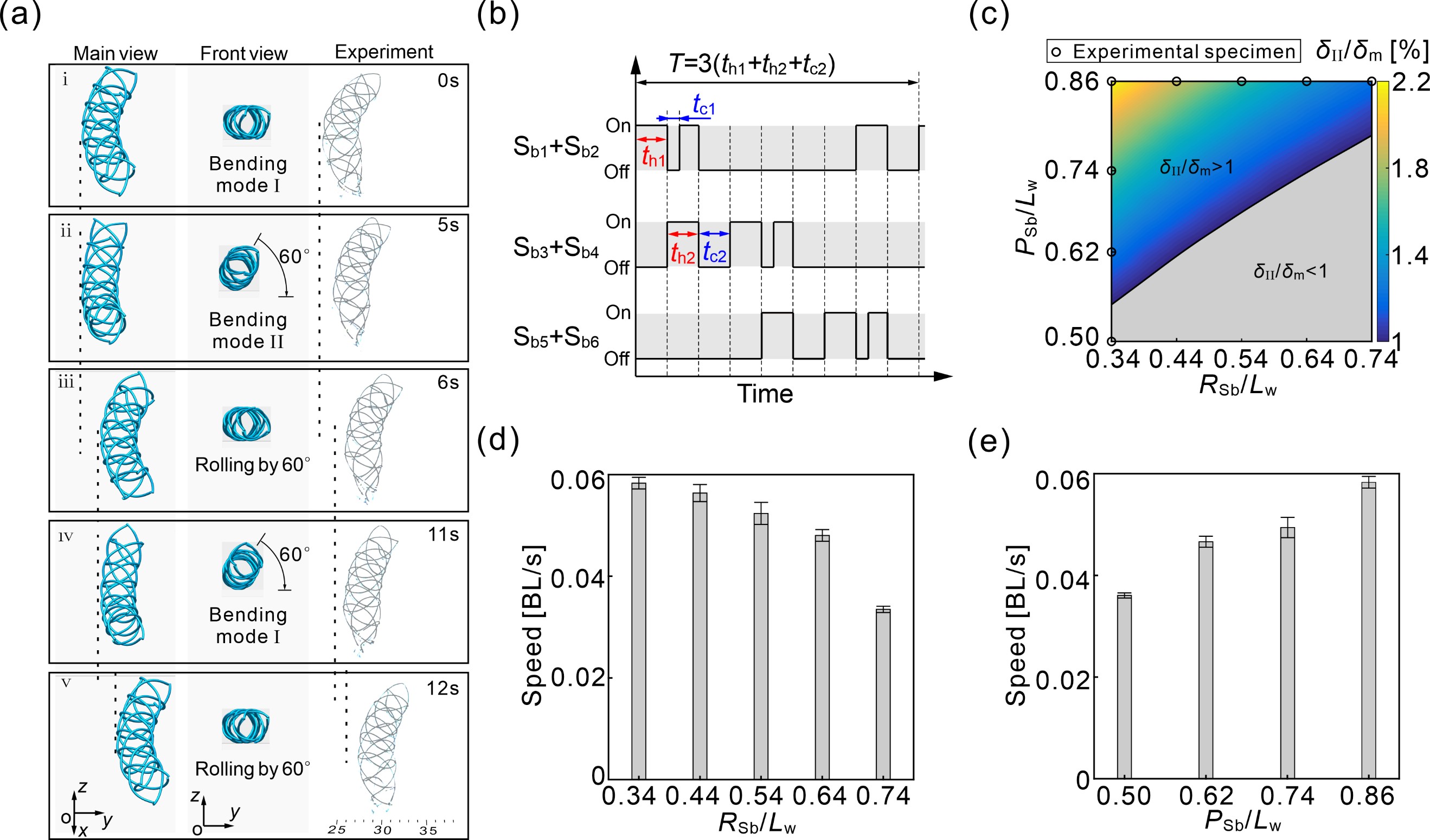

From: Date: 2025-11-14 Soft robots with multimode locomotion possess great application potential across various engineering fields due to their exceptional motion flexibility and environmental adaptability. Conventional approaches achieve multiple locomotion modes by designing a primary structure capable of different movements and then employing a series of actuators to drive each motion. Compared with these, soft robots formed and actuated by stimuli-responsive materials are significantly simpler as it does not require additional actuators, but the number of locomotion modes is limited by the relatively simple structural design. How to achieve diverse deformations and motions with a simple structure formed by smart materials has remained a core challenge. Recently, a research team of Professor Yan Chen from the School of Mechanical Engineering at Tianjin University proposed a multimode soft robot based on a single braided tube composed of shape memory alloy (SMA) wires set at distinct initial configurations. By strategically heating different wires, it can move by straight crawling, left/right turning, inchworm crawling, and rolling, without additional actuators. The research, titled “A Multimode Soft Robot Based on a Single Braided Tube” was published online in Advanced Intelligent Systems on November 6 2025. The co-corresponding authors are Professors Yan Chen and Jiayao Ma, and the co-first authors are Ph.D. student Zhenhao Jia and Professor Jiayao Ma. The research was supported by the National Natural Science Foundation of China and the New Cornerstone Science Foundation. Firstly, the contraction and elongation deformation can be realized by braiding two types of SMA wires into a single braided tube. The Sc wire is a left-hand helical characterized by a small pitch and a large helical radius, while the slender Se wire is a right-hand one defined by a large pitch and a small helical radius, as shown in Figure 1a. The braided tube with an initial length is at an equilibrium state where Sc wires are elongated and Se wires are contracted. Upon heating the Sc wires, the phase transition increases their modulus, leading to increased stress that disrupts the initial equilibrium. This causes the braided tube to undergo axial contraction, deforming towards the initial configuration of the Sc wires. Similarly, heating the Se wires causes the braided tube to elongate axially. Figure 1. Characterization of contraction/elongation deformation of the braided tube. The bending deformation can be achieved by braiding six curved helical Sb SMA wires into a single braided tube. By heating different numbers of wires, two bending deformation modes can be obtained as shown in Figure 2. Upon heating two Sb wires with the same starting point, the phase transition increases their modulus and disrupts the initial equilibrium, causing the braided tube to undergo bending mode Ⅰ towards the initial bending direction of the heated wires. On the other hand, upon heating four Sb wires together, the braided tube will undergo bending mode Ⅱ toward the common bending direction of the four heated wires. Therefore, the braided tube is capable of bending to six directions by selectively heating different wires. When bent, the barycenter of the braided tube will deviate from the helical axis, which may be used to actuate rolling locomotion. Figure 2. Characterization of bending deformation of the braided tube. In addition to the stand-alone axial and bending deformation, we can also combine them together for multimode deformation through braiding three Sc and six Sb wires. By heating different wires, the multimode braided tube deforms as shown in Figure 3. When heating two Sb wires with the same starting point, or heating the other four Sb wires together, the braided tube undergoes two distinct bending deformation modes, consistent with the finding in Figure 2. Heating two Sb with the same starting point and three Sc wires together leads to a coupled deformation of bending mode I and contraction. Elongation is realized by heating all Sb wires together, leveraging the symmetrical arrangement and the large pitch of Sb wires, while contraction is generated by heating Sc wires. Figure 3. Characterization of multimode deformation of the braided tube.

Movie S1. Deformation experiments of braided tubes To transform the elongation and contraction deformation of the braided tube into the directional crawling motion of the robot, two types of feet are designed and attached to both ends of the braided tube, as shown in Figure 4a. When the braided tube elongates, the rear feet are pinned to the ground with the rough sandpaper while the front feet slide forward with the smooth tape contacting the ground. Conversely, when the braided tube contracts, the front feet are anchored to the ground with the sandpaper surface, and the rear feet slide forward as the sandpaper strip flips and the smooth tape side contacts the ground. By alternative contraction and elongation, a periodic crawling locomotion is generated, as demonstrated in Movie S2. Figure 4. Crawling robot design and locomotion performance analysis.

Movie S2. Crawling locomotion demonstration Taking advantage of the barycenter offset caused by bending, a rolling robot is designed based on the braided tube composed of six Sb wires, without additional actuators or components. Rolling is driven solely by a controlled shift in the barycenter: while straight, the tube balances the mass along its axis; once the tube is bent at an angle direction with the plane, its barycenter deviates from the helical axis. This offset creates a gravitational torque that drives the tube roll to a new balance state, and repeated bending re-establishes the imbalance, yielding continuous roll without any extra actuators. Through alternately changing six bending directions caused by both bending mode I and bending mode II, the robot can roll on the plane, as demonstrated in Movie S3. Figure 5. Rolling locomotion and performance analysis.

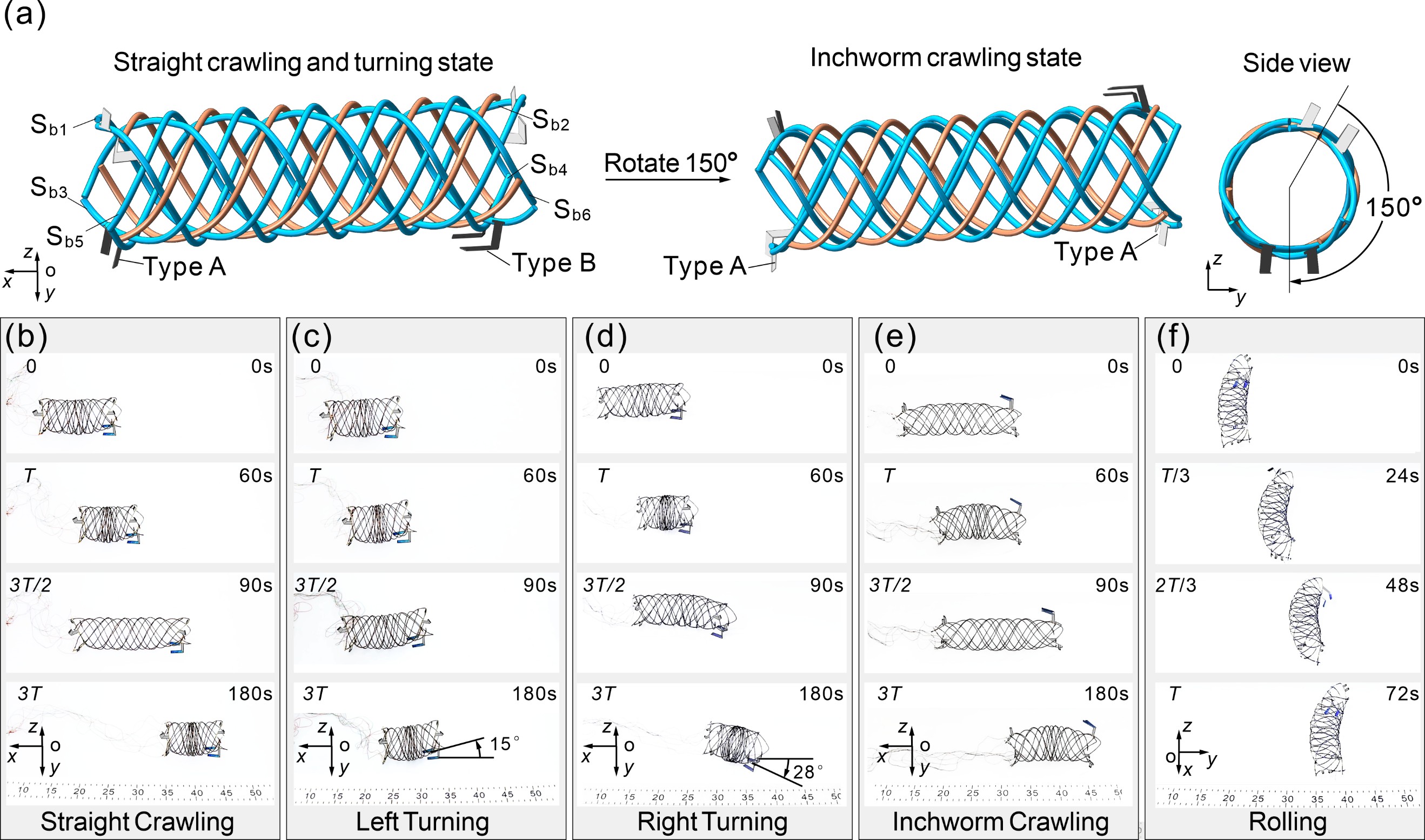

Movie S3. Rolling locomotion demonstration In addition to the single-mode robots, a multimode robot is developed by utilizing multiple deformation modes. By attaching two groups of front and rear feet to both ends of the braided tube, the robot can achieve straight crawling through contraction and elongation, left/right turning through bending and elongation, inchworm crawling through elongation and the coupled deformation of bending mode I and contraction, and rolling through two bending modes, as shown in Figure 6b-f and Movie S4. Figure 6. The soft multimode robot and locomotion demonstrations.

Movie S4 multimode locomotion demonstrations To summarize, this research presents a novel design approach for a multimode soft robot with high integration of structure and actuation, based on a single braided structure composed of SMA wires with distinct initial configurations. Leveraging the axial contraction, elongation, and bending deformation modes, a crawling robot, a rolling robot, and a multimode robot are developed and actuated without additional actuators. The proposed framework of structural design will provide useful guidance for the design of highly integrated and soft multimode robots with enhanced adaptability and performance.

Zhenhao Jia#, Jiayao Ma#*, Yan Chen*. A Multimode Soft Robot Based on a Single Braided Tube. Advanced Intelligent Systems, 2025, e202500777. |