Research

Team

Publications

News

|

New Publication: International Journal of Mechanical Sciences| Sibo Chai and Tianshu Wang published Design of a One-DOF Rigid-Foldable Wrapping Origami Pattern

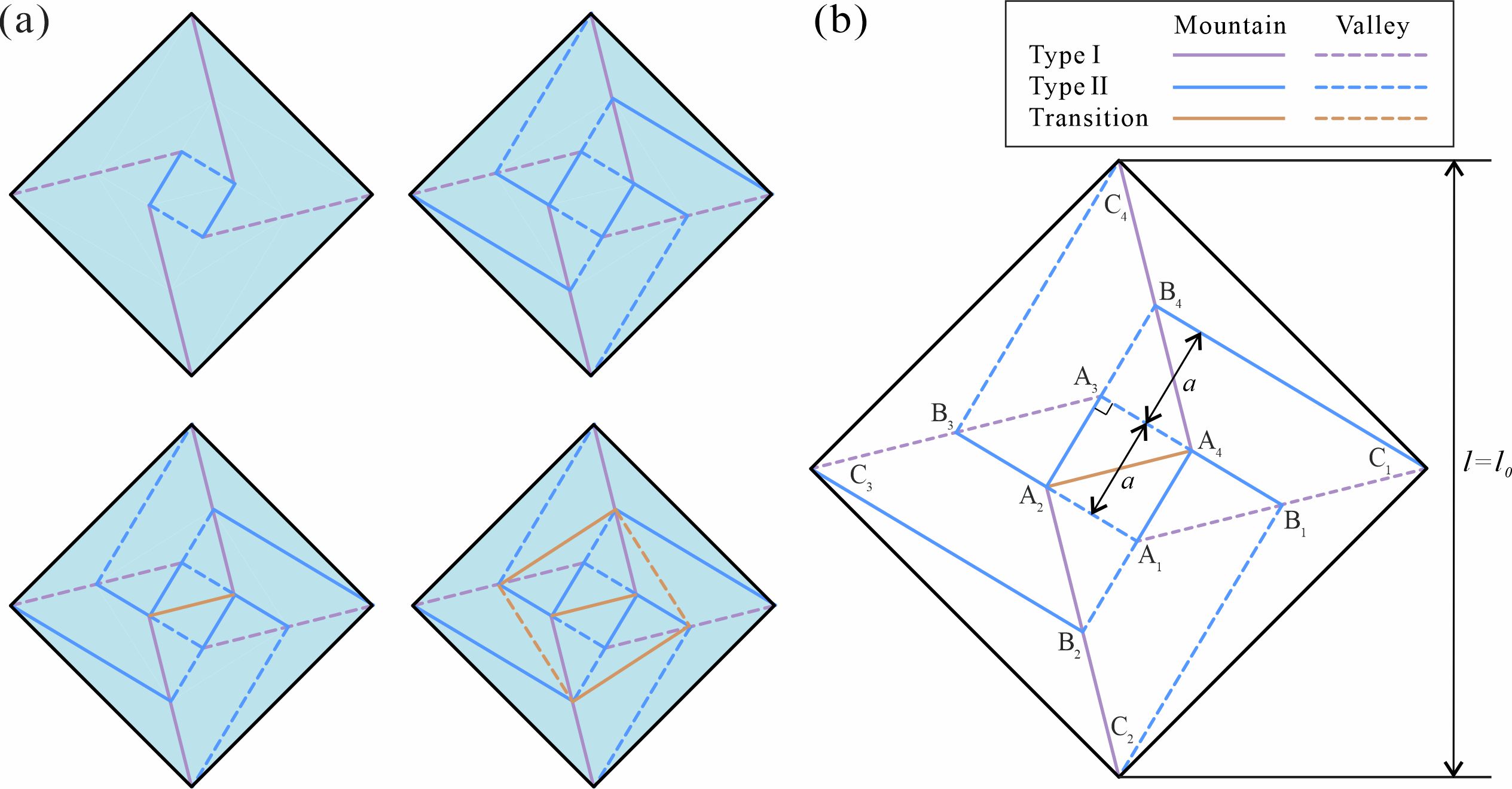

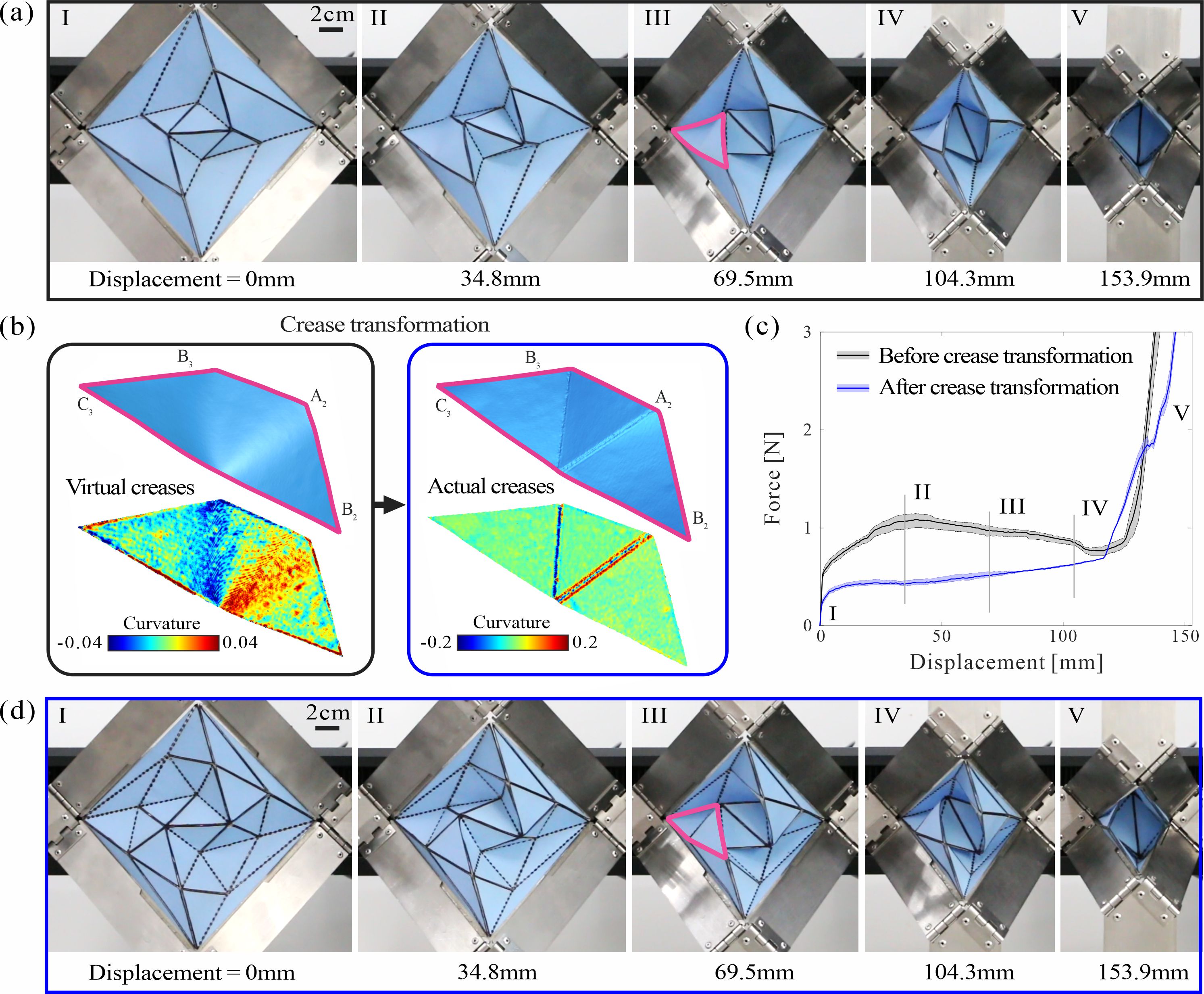

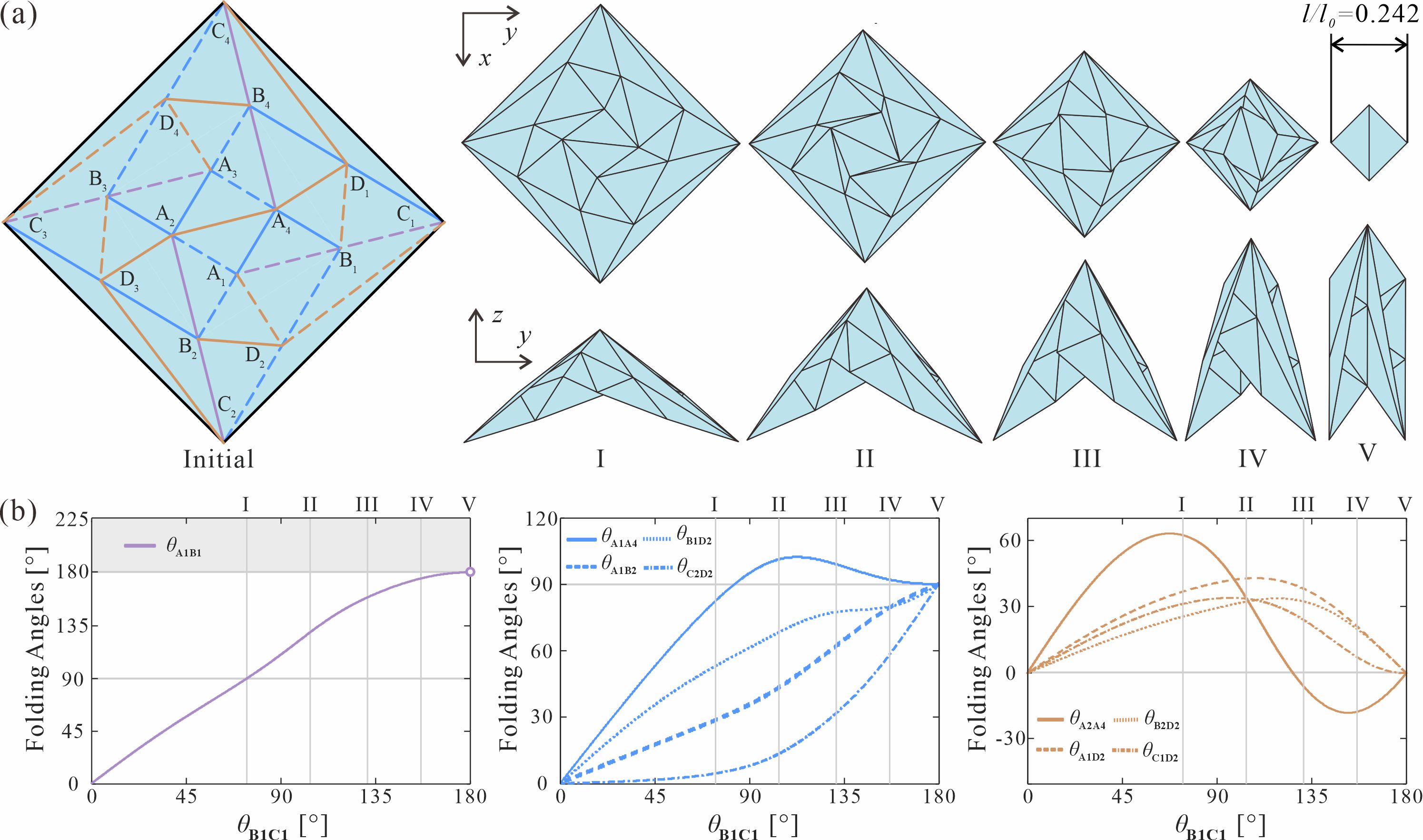

From: Date: 2025-12-01 Origami structures, characterized by their abundant design parameters and ease of manufacture, have high application potential in fields such as aerospace deployable structures, solar arrays, soft robotics, and metamaterials. The wrapping origami pattern, as a typical class of origami, has received significant research interest due to its spiral-like folding form and high folding ratio. However, most existing wrapping origami structures are non-rigid-foldable, and the few rigid-foldable designs require the introduction of cuts or possess multiple degrees of freedom (DOFs). The lack of effective single-DOF rigidly foldable designs limits the application of wrapping origami in high-precision engineering fields. Recently, the research team led by Professor Yan Chen and Professor Jiayao Ma from the School of Mechanical Engineering at Tianjin University proposed a combined experiment-driven and computation-driven design methodology, successfully designing a new one-DOF rigid-foldable wrapping origami pattern. This achievement realizes interference-free rigid folding motion and compact folding with a high folding ratio. The related research findings were published online on November 10, 2025, in the International Journal of Mechanical Sciences under the title "Design of a one-DOF rigid-foldable wrapping origami pattern". The corresponding authors of the paper are Professor Yan Chen and Professor Jiayao Ma from Tianjin University. The co-first authors are PhD student Sibo Chai and Assistant Researcher Tianshu Wang. PhD student Kaili Xi also made significant contributions to this research. This study was supported by the National Natural Science Foundation of China (Grant Nos.: 52320105005, 524B2048, 52422502). Figure 1. The non-rigid-foldable wrapping origami pattern. Starting from the traditional non-rigid-foldable wrapping origami pattern, the research team classified its creases into three types: Type 1 creases, Type 2 creases, and transition creases (Fig. 1). Through continuous loading experiments on the non-rigid wrapping pattern with transition creases removed from the trapezoidal panels, they observed the formation of V-shaped concentrated regions of virtual creases on the trapezoidal panels during folding (Fig. 2). This experimentally observed deformation mode follows the principle of minimum potential energy. By transforming these virtual creases into actual transition creases, the panel deformation in the new pattern was entirely transferred to the creases, significantly reducing the energy required for driving the folding. Figure 2. Experiment-driven design of the rigid-foldable wrapping pattern through crease transformation. Kinematic analysis using the truss transformation method confirmed that the new pattern possesses one-DOF rigid-foldability. Type 1 creases increase monotonically from 0° to 180°, Type 2 creases increase to 90°, while the transition creases oscillate around 0°, replacing the previously required panel deformation. The new pattern exhibited no physical interference throughout the folding process, achieving a maximum folding ratio of 0.242. Figure 3. Folding configurations and kinematic curves of the single-layer rigid-foldable wrapping origami. When extending the experiment-driven design to multi-layer structures, Type 1 creases were found to exceed 180° during folding, causing adjacent panels to penetrate each other and resulting in physical interference, which only disappear in the final tightly wrapped configuration (Fig. 4). Parametric studies further revealed that such physical interference could not be eliminated solely by adjusting the positions of the transition creases. Therefore, systematic design of the crease dimensions of the origami pattern was necessary to achieve a larger interference-free folding ratio within the rigidly foldable range.

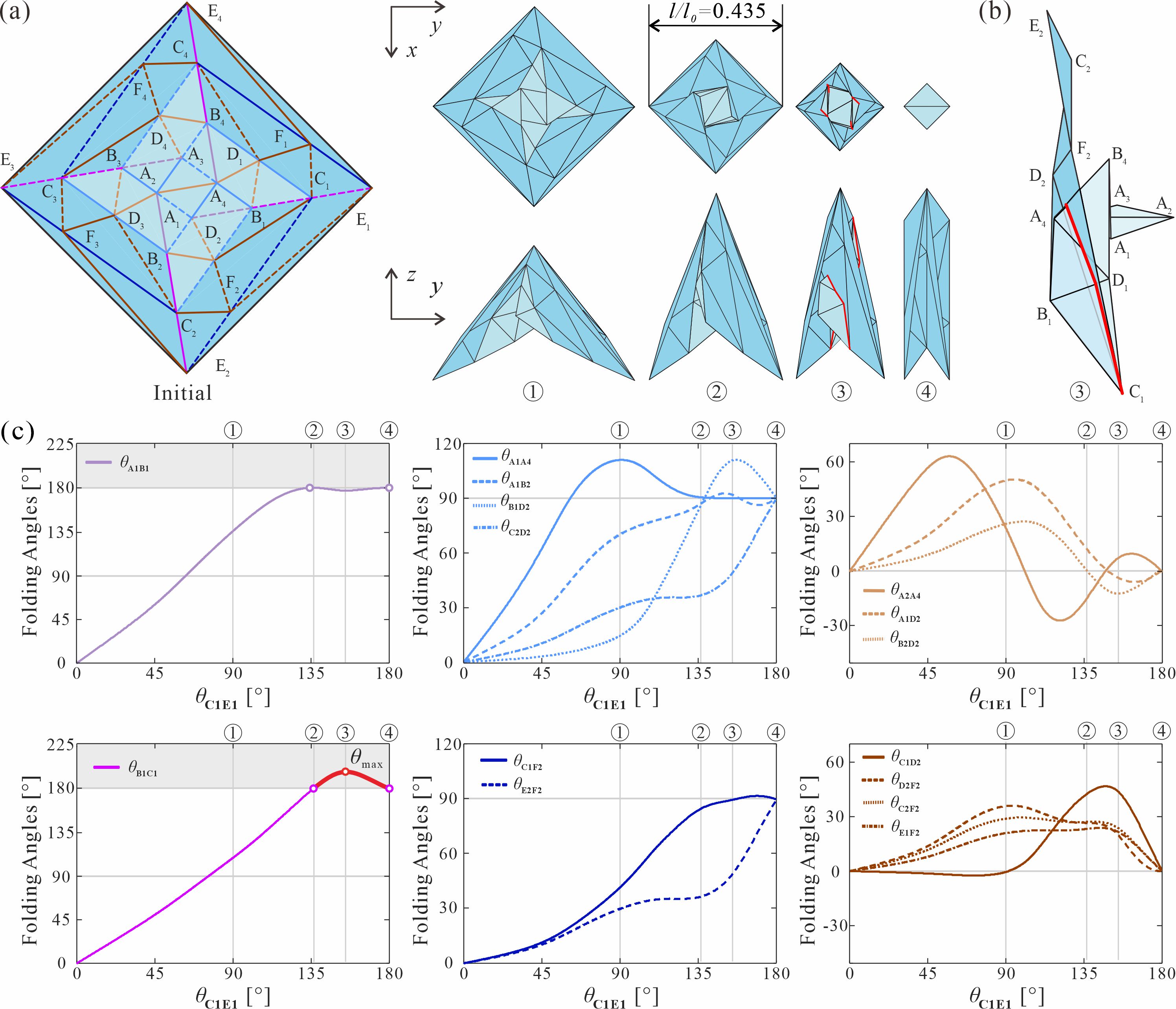

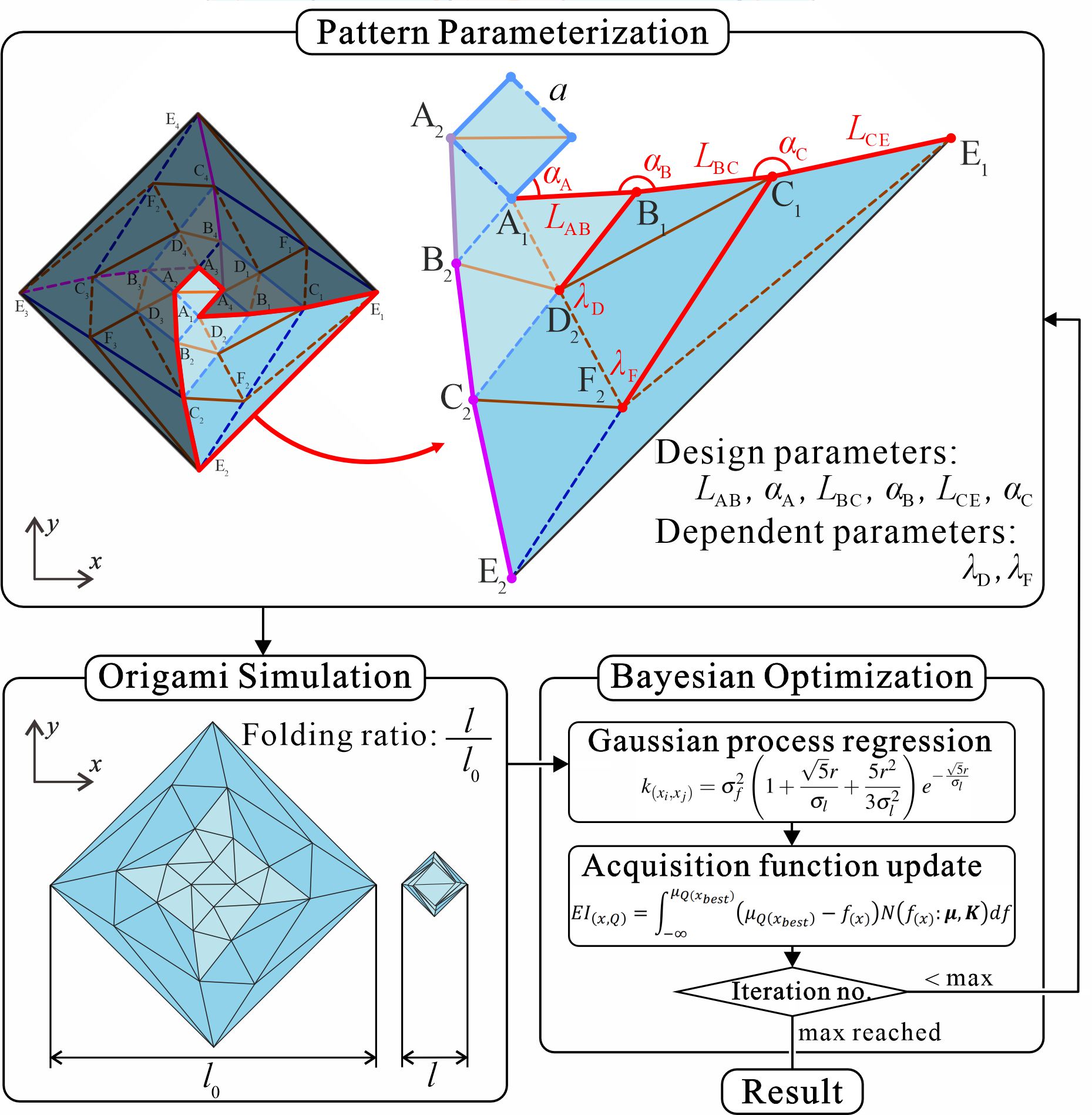

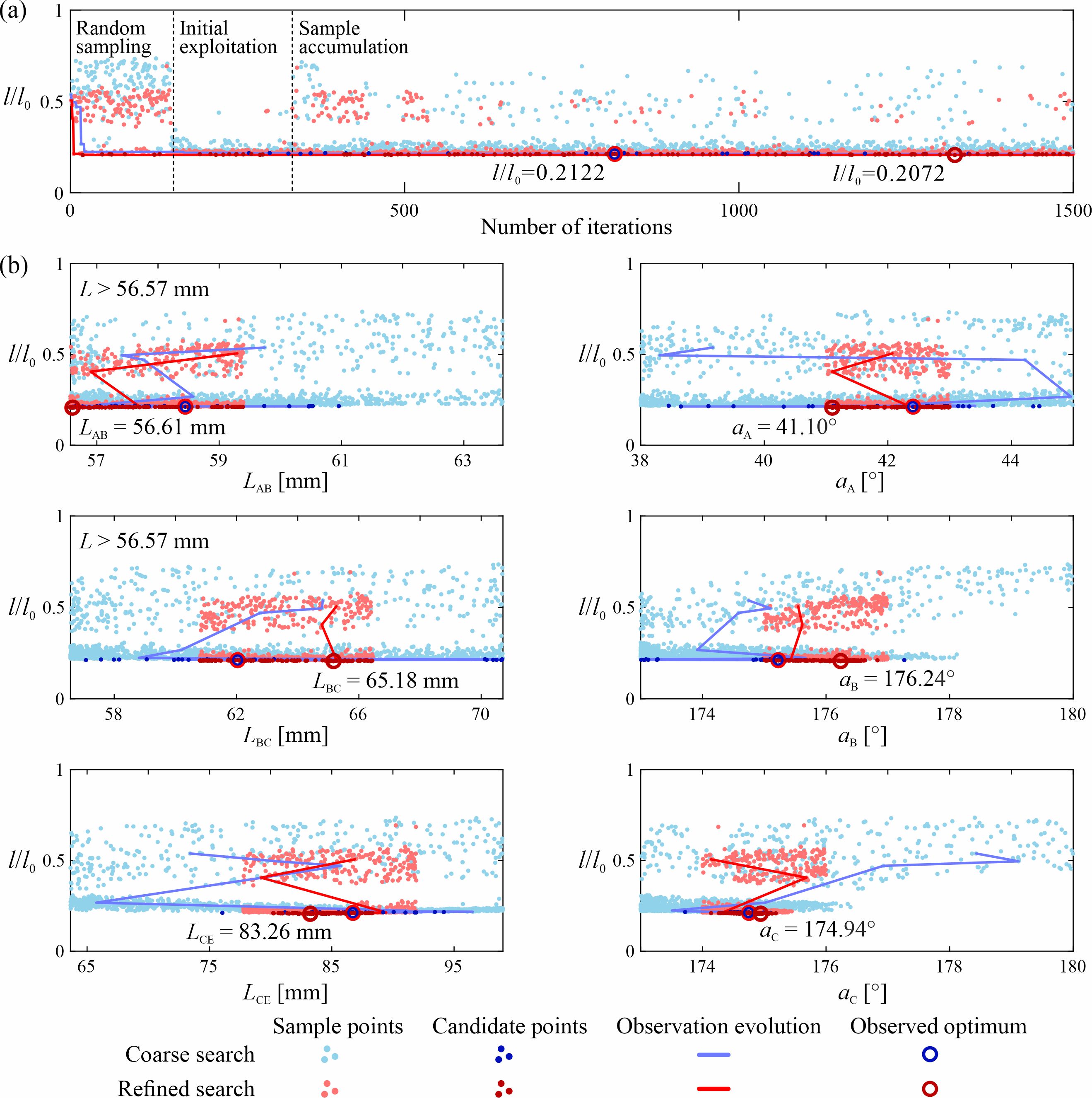

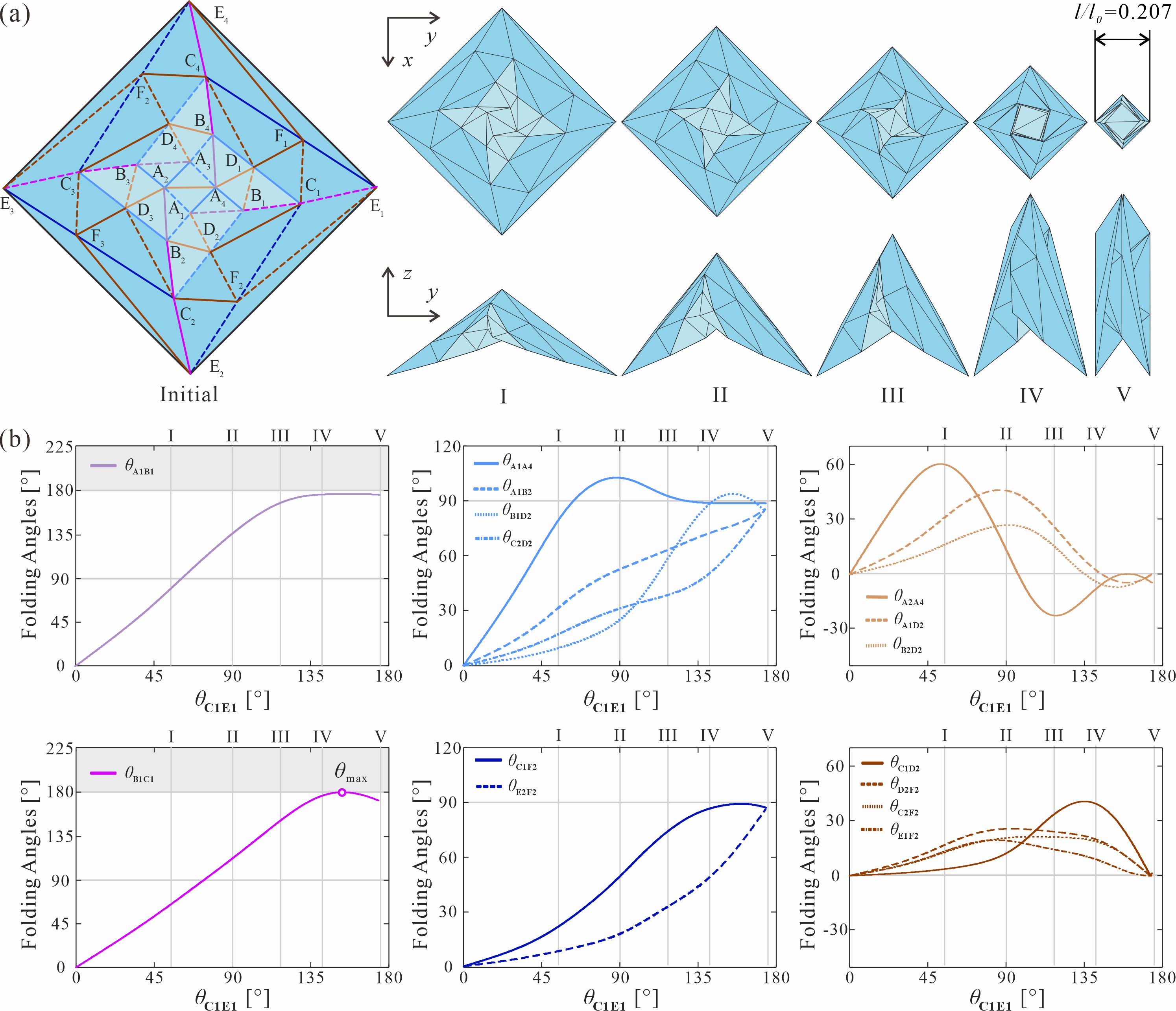

Figure 4. Kinematic curves and physical interference behavior of the two-layer wrapping origami. To address this, the research team developed a comprehensive computation-driven dimensional synthesis methodology (Fig. 5). This method combines parametric modeling, fast folding simulation, and Bayesian optimization, transforming the complex origami dimensional synthesis problem into a global optimization problem. The geometry of the Type 1 creases was accurately characterized using six independent design parameters, while the positions of virtual vertices were determined by minimizing total crease length. A quasi-static bar-hinge model was employed for efficient folding simulation, and interference detection throughout the entire folding trajectory was implemented using triangle-triangle intersection computation. Bayesian optimization was used to adjust the six independent design parameters to optimize the folding ratio before interference occurs, ensuring the final design achieved interference-free folding with a minimized folding ratio. Figure 5. Computation-driven synthesis methodology combining pattern parameterization, origami simulation, and Bayesian optimization. The optimization process consisted of two stages: a coarse search and a refined search, each completing 1500 objective function evaluations. After passing through key phases of random sampling, initial exploitation, and sample accumulation, the optimal combination of design parameters was ultimately identified (Fig. 6). Simultaneously, multiple candidate parameter sets with folding ratios within 0.005 of the optimum were generated, providing substantial design freedom and flexibility for practical engineering applications. Figure 6. Bayesian optimization results and optimal parameters. Through systematic optimization design, the final two-layer wrapping origami pattern achieved interference-free, compact, rigid folding with a folding ratio of 0.207, which is only 48% of the folding ratio (0.435) of the original two-layer pattern at the onset of interference (Fig. 7). Furthermore, experiments validated the excellent rigid-foldability and the interference-free folding process of the optimized two-layer wrapping origami. Figure 7. Folding configurations and kinematic curves of the rigid-foldable wrapping origami under optimal two-layer parameters. In summary, this research realized a one-DOF rigid-foldable wrapping origami structure through experiment-driven design and achieved interference-free compact folding for multi-layer patterns via computation-driven dimensional synthesis. This combined experiment-driven and computation-driven design methodology provides a new paradigm for the design of other rigid-foldable origami structures and deployable systems, demonstrating broad application prospects in fields such as aerospace engineering, soft robotics, and metamaterials.

Sibo Chai#, Tianshu Wang#, Kaili Xi, Jiayao Ma*, Yan Chen*, Design of a one-DOF rigid-foldable wrapping origami pattern, International Journal of Mechanical Sciences, 2026, 309, 111009. |